Applications

Industry:

Jaw stone crusher is widely used in concrete aggregate manufacturing in construction building, road, railway, highway, water conservancy and mining ore industry.

Material:

Jaw crushers are applied to quartz, granite, basalt, limestone, river stone, andesite, diabase, feldspar stone, Coal, iron ore, copper ore, gold ore, manganese ore, lead and zinc ore etc.

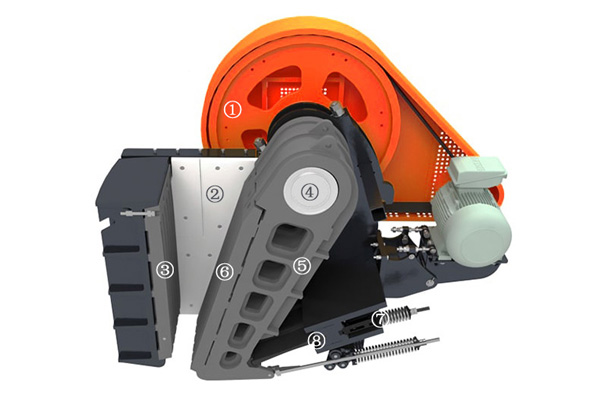

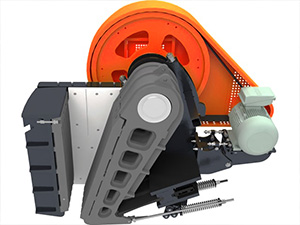

Structure

1. High Inertia Flywheels

Optimized design to generate the crushing force required for the toughest and hardest materials.

2. Wear-resistant Side Liners

Common right-hand and left-hand side liners are made of alloy steel for longer service life.

3. Jaw Plate

Jaw plates are quick and easy to install with the help of clamping wedges that fix the plates to the crusher body.

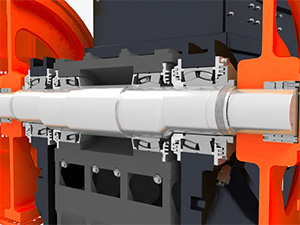

4. High Strength Eccentric Shaft

This hardest working component is precision machine control for proven high strength and reliability.

5. Solid Cast Steel Movable Jaw

Ensures highest strength while reducing the total weight.

6. Jaw Dies

Offering different liner configurations expands the applications window for the crusher.

7. Long Stroke Tension Springs

Minimize the adjustments and maintain proper toggle pre-load, preventing premature toggle seat wear.

8. High Strength Toggle Plate

Provides the correct protection of the crusher to ensure performance and long term durability.

Advantages

High crushing ratio

The main shaft is forged from hardened and tempered alloy steel with particularly large diameters to suit the heavy-duty applications.

Long Service time

High load capacity of the eccentric shaft bearings result in considerably longer service lifetimes.

Efficiency and Safety

The optimal-angle toggle plate generates extra crushing force and at the same time protects the drive system.

Economic and Durability

High quality jaw plates material and unique design ensures outstanding durability.

Parameters

| Model | Max. Feeding Size(mm) | Adjustable Discharge Opening(mm) | Capacity (t/h) | Power (kw) | Overall Dimensions (mm) | Weight (t) |

PE150×250 (6×10 IN) | 125 | 10-40 | 1-3 | 5.5 | 922×745×933 | 0.7 |

PE200×300 (8×12 IN) | 150 | 15-30 | 3-15 | 10 | 1012×945×1073 | 1.5 |

PE250×400 (10×16 IN) | 200 | 20-60 | 5-20 | 15 | 1150×1275×1240 | 2.8 |

PE400×600 (16×24 IN) | 350 | 40-100 | 15-60 | 30 | 1700×1732×1653 | 6.5 |

PE500×750 (20×30 IN) | 425 | 50-100 | 50-100 | 55 | 2035×1921×2000 | 10.3 |

PE600×900 (24×36 IN) | 500 | 65-160 | 60-130 | 75 | 2290×2206×2370 | 16 |

PE750×1060 (30×42 IN) | 630 | 80-140 | 110-250 | 110 | 2620×2302×3110 | 27 |

PE900×1200 (36×48 IN) | 750 | 100-200 | 160-380 | 132 | 3789×2826×3025 | 46.5 |

PE1000×1200 (40×48 IN) | 850 | 200-300 | 315-550 | 132 | 3889×2826×3025 | 56 |

PE1200×1500 (48×60 IN) | 1000 | 150-350 | 400-800 | 200 | 4930×3148×3560 | 88 |

PE150×750 (6×30 IN) | 120 | 18-48 | 5-16 | 15 | 1205×1495×1203 | 3.5 |

PE250×750 (10×30 IN) | 210 | 25-60 | 15-30 | 25 | 1380×1750×1540 | 5.5 |

PE250×1000 (10×40 IN) | 210 | 25-60 | 15-50 | 35 | 1580×1992×1380 | 7.35 |

PE250×1200 (10×48 IN) | 210 | 25-60 | 20-60 | 40 | 2192×1900×1950 | 9.7 |

PE300×1300 (12×52 IN) | 350 | 20-90 | 30-90 | 55 | 2256×2100×1960 | 11.7 |

Contact Us

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU