Applications

Stone crushing plant Introduction

Stone/Aggregate crushing production line has been widely used for producing gravel, limestone, ballast, basalt, granite, and sand stone manufacturing plant. For highway, high railway, hydroelectric dam construction, bulid construction fields and so on.

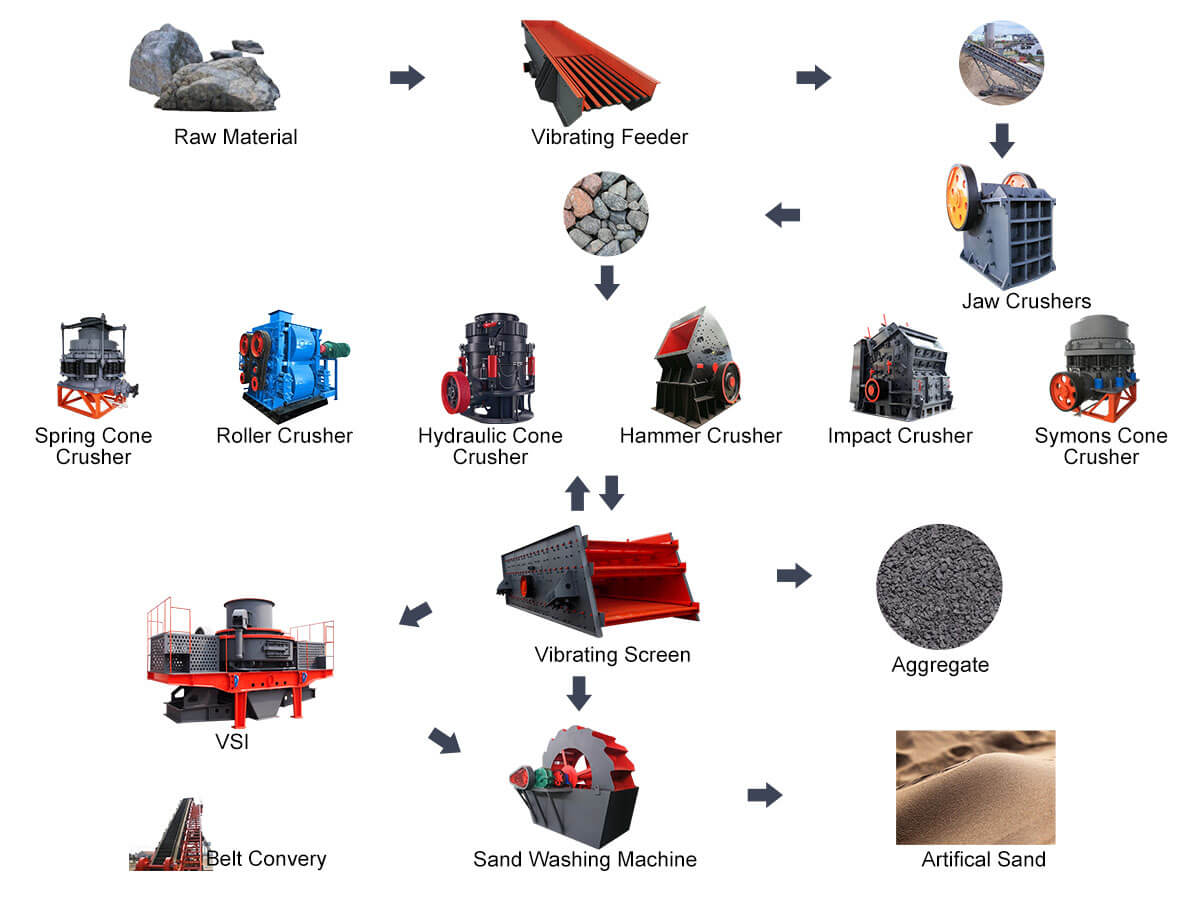

Fixed Stone crushing plant commonly is a 3 stage crushing plant, consists of a vibrating feeder, suitable crushers such as jaw crusher (primary crusher), cone crusher, impact crusher(according to the material and capacity), vibrating screen, belt conveyor and Central electric control system, etc. It's designed throughput generally is 50-1000 t/h. Sand washing and other machines can be added to this line to meet the various customers’ requirements.

Stone Crushing Process

The stationary crushing plant has fixed plant structures. The crushing processes are as follows.

◑ Feeding

Stones are blasted down from the mountain,and large stones are fed into vibrating feeder by dump trucks.

The vibration feeder will feed the stone into the coarse broken evenly by jaw crusher. It is the GradeⅠ crushing;

◑ Fine Crushing

the broken stone will be transported to the fine broken stone through the belt conveyor. It is the GradeⅡ crushing.

In the secondary crushing, it mainly use the following stone crushers:

Jaw crusher is mainly used to crush all kinds of ores and medium-sized particles of materials.

Impact crusher is used in coarse crushing, intermediate crushing, and fine crushing of materials like limestone, coal, calcium carbide, quartz, dolomite, sulfide iron ore, gypsum, chemical raw materials, etc.

Cone crusher improves the production capacity and crushing efficiency. It can be adopted to almost all types of materials from stone production to various ores crushing. Cone crushers can perform the unparalleled crushing function in operations of coarse crushing, fine crushing, and superfine crushing. Cone crusher can finely crush various ores and rocks with different high hardness, like iron ore, nonferrous metal, emery, bauxite, quartz sand, brown aluminum oxide, perlite, basalt, etc.

◑ Sand Making and Screening

On the one hand, the crushed stone can be used directly as concrete aggregate in building industry. On the other hand, the crushed stone can be transported by the belt conveyor to the sand making machine for fine crushing. The crushed material is then screened through the circular vibrating screen for coarse sand, medium sand, fine sand and other specifications.

To meet the strict requirements, we need to add the sand washing machine behind fine sand. Sand washing machine discharge sewage can be recycled by fine sand recycling machine, reducing environmental pollution and improving the production of sand.

Contact Us

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU