The diatomite crushing production line is the main process of crushing and processing diatomite. The processed diatomite has greater application value. The production line has greater processing capacity and lower unit energy consumption, which can effectively reduce the cost of users in production. The diatomite crushing production line mainly consists of the following products:

1. Jaw crusher

Jaw crusher is also known as the jaw broken machine, it is in the diatomite coarse broken necessary equipment. We have Stationary PE/Jaw Crusher, PEW Series European jaw Crusher for medium scale diatomite rock crushing, Mini PEM Series Small Jaw Crusher for small scale, and portable jaw crusher plant for convenience.

Jaw Crusher Machines have the following advantages:

(1) The crushing chamber of the equipment can break diatomite evenly and high-yield, and the crushing chamber is deep, so the amount of diatomite treated in a unit time is large, which effectively improves the crushing efficiency of the crusher and increases its output.

(2) It is made of special materials, especially the wear parts made of lighter weight and stronger wear resistance materials, which increases the service life of the equipment and reduces the cost input of users in production.

(3) Users can adjust the particle size of the discharge port according to their own production requirements, so that the broken material can meet the needs of users as far as possible, and replace the traditional gasket adjusting device with the adjusting device of the wedge, so that users in the adjustment process is more convenient and fast.

(4) The flywheel of the equipment adopts a special design concept, which makes the equipment more stable in operation and reduces unnecessary equipment maintenance costs for users.

The impact crusher is a crushing equipment with high efficiency and energy saving produced by our company with the introduction of new technology. Its performance characteristics in the crushing process are as follows:

1) The price is cheap. In unit time, the amount of diatomite treated is almost the same as that of the cone crusher, but the price of the equipment is one third of the price of the cone crusher, which can save a large amount of expense for the user to buy the equipment.

(2) The broken diatomite particles are complete and uniform, with a high yield of finished products, which improves the crushing efficiency of users in production and effectively reduces users' operating costs.

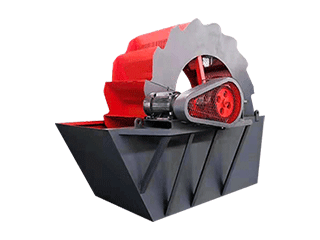

Circular vibrating screen is a special equipment for screening broken diatomite, which plays a very important role in the production line. It is generally used for screening coarse and finely broken diatomite materials, and has the advantages of simple working principle and operation.

Vibrating feeder is a kind of feeding device, which can transfer diatomite in the silo to the receiving device at a fixed time and in a fixed quantity, which not only avoids the problem of plugging of the feeding mouth, but also increases the production efficiency of users. The device has the characteristics of simple structure and convenient operation.

Belt conveyor is an important transport equipment in the production line, it can be connected to the equipment, and has the characteristics of long distance, large transport volume, flexible steering, etc., under its role can increase the profit brought by its production, the equipment in the production can not only be carried out alone, but also a number of equipment joint operation.

Info request

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU