Applications

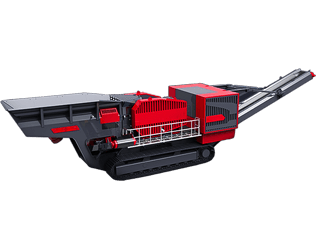

Product Introduction:

Mobile Cone Crusher Plant is mainly used in fine grinding operation field, in the production of sand aggregate, mobile cone crusher can replace impact crusher to product higher hardness and more fine-grained sand aggregate. Cone crusher can adjust to different cavities according to actual requirements, which has extended the application range of mobile cone crushers.

Feeding size: 160-240mm

Production capacity: 40-390t/h

Applications: Recycling of mines, coal mines, garbage and construction waste, earth and stone works, urban infrastructure, roads or construction sites.

Applicable materials: artificial sand making of river pebble, rock (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, and stone chips

Mobile cone crusher plant features:

1. High flexibility

2. Compact structure and simple to operate

3. Saving operation costs

4. Higher applicability

5. Stable performance, easy maintenance

6. Flexible configuration

Working principle:

Vibrating feeder feeds materials into cone crusher, the cone crusher makes a preliminary crushing, through a circular vibrating screen to constitute a closed system, realizing the cycle crushing of materials. And then the finished products are transported out by belt conveyor and crushed recurrently.

Structure:

All components of the cone moving crusher are placed on the moving frame, including: stable and sturdy chassis, efficient cone crusher, screening equipment, belt conveyor, electric motor and electrical control system,and optional hydraulic auxiliary system, environmental dust removal system, maintenance platform and other components.

Scope of use:

1. It is widely used in mines, recycling of coal mines, garbage and construction waste, earth and stone works, urban infrastructure, roads or construction sites.

2. Treatment of topsoil and other materials; separation of viscous aggregates; construction and blasting industry; screening after crushing; quarrying industry.

3. River pebble, rock (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, and mechanism sand of stone chips

Parameters

DWP series mobile cone crushing and screening plant | ||||||||||

Category | Type | |||||||||

Name | DWP200YHP23S | DWP200YHP33S | DWP200YHP34S | DWP300YHP42S | DWP300YHP44S | DWP300YHP53S | DWP400YHP44S | DWP400YHP52S | DWP400YHP53S | DWP400YHP54S |

Shipping size | ||||||||||

Length | 11840 | 13920 | 13920 | 13720 | 14800 | 14700 | 15500 | 15250 | 15690 | 15690 |

Width | 2780 | 2780 | 2780 | 2780 | 2865 | 3040 | 2865 | 3000 | 3290 | 3300 |

Height | 4350 | 4360 | 4460 | 4350 | 4300 | 4220 | 4300 | 4500 | 4550 | 4510 |

Weight | 31.8 | 33 | 34.4 | 37.3 | 42.9 | 45.1 | 55.6 | 55.8 | 53 | 54.4 |

Cone crusher | ||||||||||

Type | YHP200 | YHP200 | YHP200 | YHP300 | YHP300 | YHP300 | YHP400 | YHP400 | YHP400 | YHP400 |

Maximum feeding size | 50-160 | 50-160 | 50-160 | 60-180 | 60-180 | 60-180 | 80-240 | 80-240 | 80-240 | 80-240 |

Outlet adjustment range | 9-32 | 9-32 | 9-32 | 9-32 | 9-32 | 9-32 | 9-51 | 9-51 | 9-51 | 9-51 |

Vibrating screen | ||||||||||

Type | 3YK6X1235 | 3YK6X1548 | 4YK6X1548 | 2YK6X1860 | 4YK6X1860 | 3YK6X2160 | 4YK6X1860 | 2YK6X2160 | 3YK6X2160 | 4YK6X2160 |

Belt conveyor | ||||||||||

Type | B650X7.5Y | B800X7.4Y | B800X7.4Y | B1000X8.2Y | B1000X8.2Y | B1000X6.5Y | B1000X8.2Y | B1000X8.2Y | B1000X8.2Y | B1000X8.2Y |

Frame axle number | ||||||||||

Number of axes | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

Remarks: The above parameters are for reference only. If there are any updates or changes, the technical data shall prevail. | ||||||||||

Note:

1. The processing capacity is the data when the density of the broken material is 1.6x103 kg/m3. The production capacity is related to the physical properties of the crushed material, the feeding mode, the feeding granularity and its composition;

2. Our products are constantly updated and improved, Devo reserves the right to change parameters and design without first notifying the user;

3. The above product configuration is not necessarily the factory standard configuration. Please consult us in detail when purchasing.

Contact Us

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU