River Pebble introduction:

The main chemical composition of the river pebble is silica, followed by a small amount of iron oxide and trace amounts of manganese, copper, aluminum, magnesium and other elements.It is an ideal building material with hard quality, natural stone properties resistant to pressure, abrasion and corrosion.

The river pebble production process uses gravel of 0-40mm as raw material.Using vertical shaft impact crusher (sand making machine) on the production line configuration,this crusher is a new sand making machine of Dewo. It is characterized by high crushing efficiency (with fine crushing and coarse grinding function), simple structure, convenient installation and maintenance, low running cost and excellent product granularity (in cube and needle-like content less).

Application fields:

Cement concrete, asphalt concrete and various stable soil materials in construction engineering, as well as road, bridge and culvert, tunnel light highway engineering.

Equipment configuration:

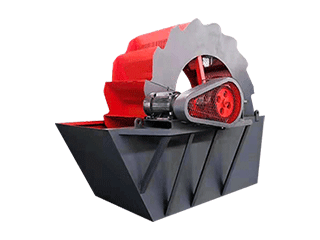

feeder, cone crusher, XV sand making machine, sand washing machine, YK6X series circular vibrating screen, belt conveyor, etc.

River pebble processing:

There are river pebble resources, which vary from place to place. Therefore, when configuring the equipment, the wear resistance of the solution should be put in the first place. Large particle size can refer to the crushing of granite and basalt; small particle size needs to be pre-screened to reduce production cost;

Take the river pebbles below 200mm as an example:The material is pre-screened in the raw material warehouse through the feeder and belt conveyor to the 1# vibrating screen. The material larger than 40mm enters the cone crusher to crush, and the 5-40mm enters the vertical impact crusher for crushing,0-5mm enters the sand washing machine, and the finished product is directly discharged after cleaning.The crushed product of the cone crusher enters the 2# vibrating screen and is screened.The return cone crusher larger than 40mm breaks and breaks again, forming a closed loop,less than 40mm into the vertical impact crusher crush.The material from the vertical impact crusher enters the 3# vibrating screen,more than 20mm returning vertical impact crusher to break, forming a closed loop.Material less than 20mm is transported to the finished product pile via a belt conveyor,according to the cleanliness of the raw materials, it is considered to send the materials of 0-5mm to the sand washing machine for cleaning.

River pebble processing technology:

The sand production line has reasonable configuration, high degree of automation, low operating cost, high breaking rate, energy saving and environmental protection, large output and easy maintenance. The machined sand produced meets the national construction sand standard, the product has uniform particle size, good granular shape and reasonable gradation.

Remarks:The equipment configuration of the sand production line is mainly determined by the customer's specifications for the sand and the output and the use of the sand.We provide solution and technical support, configure the process according to the customer's production site, and strive to achieve a reasonable and economical production line for customers.

Info request

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU