Applications

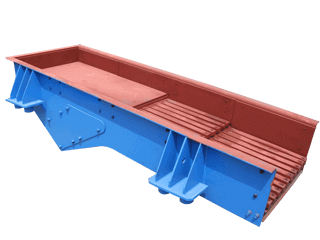

Product Introduction:

ZK6X series linear vibrating screen is mainly used for screening and grading powdery and granular materials. Vibration motor excitation is used as the vibration source, so that the material is thrown up on the screen and linearly moved forward. The material is evenly distributed from the feeder. Entering the feed port of the screening machine, several kinds of sieve tops and sieves are produced through the multi-layer screen, and are respectively discharged from the respective outlets. It has the characteristics of low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic material discharge, etc. It is more suitable for assembly line operation.

Working Principle:

Linear vibrating screen is driven by double motors which make the motions of synchronous and reverse rotation, and the exciting force produced by eccentric block is offset in parallel to the motor axis direction while it is summed to the resultant force in a direction perpendicular to the motor axis, thus the screen machine motion trajectory is a straight line. The two motor shafts shaped a slope angle with the screen surface combine with the resultant force of the exciting force and the gravity of materials, which throw the materials forward in a straight way and achieve the purpose of sifting and grading. It can be used in the production line to materialize the automatic operation. Meanwhile, it features low consumption, high efficiency, simple structure, easy maintenance, fully-closed structure and non dust overflow, etc.

Product Feature Advantages:

1.Use the unique eccentric structure to produce powerful vibrating force.

2.The beam and case of screen are connected with high strength bolts without welding.

3.Simple structure and easy maintenance.

4.Adopting tire coupling and soft connection makes operation smooth.

5.High screen efficiency, great capacity and longer service life.

Parameters

Model | Screen Surface | Max Feeding Size (mm) | Motor Power (kw) | Capacity(t/h) | Weight (kg) | ||

Deck Size(m2) | Mesh (mm) | Structural | |||||

ZK6X1230 | 3.6 | 0.25-50 | Punched Polyurethane Stripped and Seamed | <250 | 4×2 | 7.2-144 | 2693 |

ZK6X1445 | 6.3 | 0.25-50 | <250 | 7.5×2 | 12.6-252 | 4040 | |

ZK6X1645 | 7.32 | 0.25-50 | <250 | 11×2 | 95-280 | 4572 | |

ZK6X1845 | 8.1 | 0.25-50 | <250 | 11×2 | 16.2-234 | 5436 | |

ZK6X2060 | 12 | 0.25-50 | <250 | 15×2 | 24-480 | 7558 | |

ZK6X2460 | 14.4 | 0.25-50 | <250 | 15×2 | 28.8-576 | 9235 | |

ZK6X3060 | 18 | 0.25-50 | <250 | 22×2 | 17.5-525 | 11062 | |

ZK6X3660 | 21.6 | 0.25-50 | <250 | 22×2 | 43.2-864 | 14390 | |

2ZK6X1230 | 3.6 | 0.25-50 | <250 | 5.5×2 | 7.2-144 | 3740 | |

2ZK6X1445 | 6.3 | 0.25-50 | <250 | 15×2 | 12.6-252 | 6883 | |

2ZK6X1645 | 7.32 | 0.25-50 | <250 | 15×2 | 95-280 | 8654 | |

2ZK6X1845 | 8.1 | 0.25-50 | <250 | 15×2 | 16.2-234 | 8116 | |

2ZK6X2060 | 12 | 0.25-50 | <250 | 22×2 | 24-480 | 10875 | |

2ZK6X2460 | 14.4 | 0.25-50 | <250 | 22×2 | 28.8-576 | 13560 | |

2ZK6X3060 | 18 | 0.25-50 | <250 | 37×2 | 17.5-525 | 18253 | |

2ZK6X3660 | 21.6 | 0.25-50 | <250 | 45×2 | 43.2-846 | 254 | |

Series; deck size; mesh; max feeding size; capacity; weight

Contact Us

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU