Applications

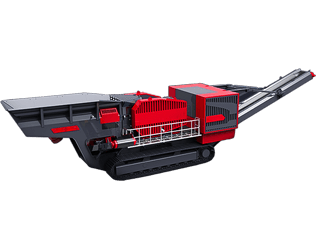

Product introduction:

Mobile Impact Crusher Plant adopt new technology and choose high quality High-chromium plate hammer and Wear- resisting impact plate. The big crushing ratio and good particle shape make mobile impact crusher owns a broader application

Feeding size: 400-1520mm

Production capacity: 50-250t/h

Applications: Recycling of mines, coal mines, garbage and construction waste, earth and stone works, urban infrastructure, roads or construction sites.

Applicable materials: limestone, granite, andesite, ore tailings, construction waste, etc.

Mobile impact crusher plant features:

1. It is high performance XF series impact crusher

2. Vehicular feeder, vibrating screen, belt conveyor

3. Traction steering shaft, be convenient to highway transportation

4. Vehicle installation, equipment can be installed on the scene conveniently

5. Be equip with motors and control box

6. Good mobility, tight structure and easy to use

7. Stable function, easy maintenance and flexible configuration

8. Decreasing cost, saving expense

Working principle:

Materials are transported to the impact crusher through the feeder, after the primary crushing of jaw crusher, using the circular vibrating screen to realize recycling crushing. The finished materials are transported out by the belt conveyor to be crushed continuously. Mobile impact crusher can remove circular vibrating screen according to the actual production needs to realize the primary crushing directly. It has the advantage of simple and flexible operation.

Structure

The parts of mobile impact crusher includes: frame, impact crusher, feeder, vibrating screen, belt conveyor, motor and control box.

Scope of use:

1. It is widely used in mine, quarrying, rubbish, the recycling of construction waste, earth and stone works, urban infrastructure, road, building site and so on.

2. Handle topsoil and other various materials; separating viscous concrete aggregate, the screening after crushing

Manufactured sand for river pebble, rock (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, aggregate chips and so on.

Parameters

DWP series mobile impact crusher plant | ||||

Category | Type | |||

Name | DWP391XF | DWP471XF | DWP472XF | DWP511XF |

Shipping size | ||||

Length | 10800 | 11400 | 11490 | 12000 |

Width | 2780 | 2780 | 2880 | 2865 |

Height | 4170 | 4300 | 4470 | 4500 |

Weight | 30 | 39.3 | 46.3 | 42 |

Impact crusher | ||||

Type | XF391P(T) | XF471P(T) | XF472P(T) | XF511P(T) |

Feeding port size | 630X1100 | 740X1100 | 760X1450 | 1080X1550 |

Maximum feeding size | 400 | 500 | 500 | 600 |

Capacity(m3/h) | 50-80 | 70-120 | 100-180 | 160-250 |

Vibrating feeder | ||||

Type | FGT271 | FGT351 | FS371 | FS431 |

Silo volume | 3.2 | 7.6 | 9 | 10 |

Silo width | 2200 | 3150 | 3290 | 3000 |

Main belt conveyor | ||||

Type | B800X7.0Y | B800X7.5Y | B1000X7.2Y | B1000X8Y |

Side belt conveyor (optional) | ||||

Type | B400X2.7Y | B500X2.7Y | B500X2.7Y | B500X2.7Y |

Iron remover (optional) | ||||

Type | RCYD-8.0 | RCYD-8.0 | RCYD-10.0 | RCYD-10.0 |

Frame axle number | ||||

Number of axes | 2 | 2 | 2 | 3 |

Remarks: 1. The above parameters are for reference only. If there are any updates or changes, the technical data shall prevail. 2. Only the main belt conveyor is shown in the table, and other related belt conveyors are shown in the drawing paper. | ||||

Note:

1. The processing capacity is the data when the density of the broken material is 1.6x103 kg/m3. The production capacity is related to the physical properties of the crushed material, the feeding mode, the feeding granularity and its composition;

2. Our products are constantly updated and improved, Devo reserves the right to change parameters and design without first notifying the user;

3. The above product configuration is not necessarily the factory standard configuration. Please consult us in detail when purchasing.

Contact Us

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU