Aggregate for highway building Introduction

In the construction of expressway, high requirements are placed on the aggregate shape and gradation of concrete aggregates, especially the pin-like content in basalt (diabase) gravel. In order to solve the requirements of particle size and gradation, particle shape, consistency of particle composition, cleanliness and particle content of 0.075mm, Dewo has added a new sand making machine in the production line configuration to better meet the highway cement and asphalt. Wait for the requirements of sand and gravel aggregates.

Applicable materials: granite, basalt, diabase and other hard materials

Application areas: highways, urban construction, airport construction and other industries

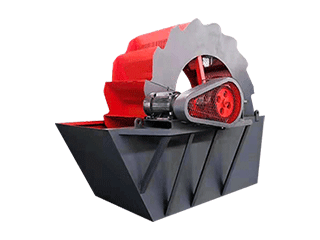

Equipment configuration: vibrating feeder, jaw crusher, hydraulic cone crusher, circular vibrating screen, vertical shaft impact crusher, belt conveyor

Production line details

In the construction of expressway, high requirements are placed on the aggregate shape and gradation of concrete aggregates, especially the pin-like content in basalt (diabase) gravel. In order to solve the requirements of particle size and gradation, particle shape, consistency of particle composition, cleanliness and particle content of 0.075mm, Dewo has added a new sand making machine in the production line configuration to better meet the highway cement and asphalt. Wait for the requirements of sand and gravel aggregates.

Expressway aggregate production process

The mined stone is firstly fed by the vibrating feeder to the jaw crusher for preliminary crushing. The secondary crushing is completed by the cone crusher. The material broken by the cone is sieved on the vibrating screen. The material larger than 40mm is returned to the cone and broken again. A closed loop is formed, and the material less than 40 mm enters the vertical impact to break and shape. The finished product sieved by the vertical impact material is sieved, and the returning vertical impact breaking cycle of more than 20 mm is broken, and the materials less than 20 mm are conveyed to the respective finished material piles by the belt conveyor.

Expressway aggregate production line performance

1. The sandstone production line is highly automated;

2. It has high production efficiency, low operating cost, large output and high profit;

3. The size of the discharge material is adjustable, the breaking rate is high, and energy saving;

4. The finished stone has uniform particle size and good granular shape, which is in line with the national high-speed material standard.

Production process of aggregate for highway

Remarks:

The production line is mainly based on the actual material size and the customer's requirements for product granularity. According to different production site conditions, Dvor engineers can provide customers with process planning and technical support, and can also design non-standard according to the actual installation conditions of customers. Supporting components, etc., and strive to achieve a reasonable and economical production line for customers.

Info request

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU