Applications

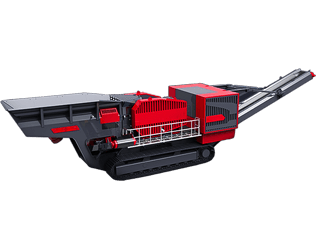

Product Introduction:

Tracked Mobile Sand Making Machine, full name vertical shaft impact crushing plant. VSI crushing plant has reached the world advanced level. The plant adopts first level mobile crushing and screening technology which fully meets client’s requirements for mobile crushing and changes your profit mode.

Scope of use:

It can be widely used in Mining, metallurgy, construction, highway, railroad, and water conservancy, etc.. The main raw materials are River pebble, rock (limestone, granite, basalt, diabase, andesite, etc.)

Product Features & Advantages:

(1) Fuel oil saving rate can reach 25%, and the sieving mode is not only in line with environmental protection but low cost.

(2) Convenient transport, no harm to road, multifunctional equipments and wide application scope.

(3) Turning in place with the capability of all-wheel drive, standard configuration, fast equipment changing, perfect protection system, best fit in narrow and complicated terrains.

(4) Light weight, small size and best fit in narrow place.

(5) The moving screen equipment uses double-deck sieving machinery, which main frame equipped with excellent grid screening gallery, can stand freely without support.

(6) The attaching power package is the most optimized design.

(7) Mechatronic-hydraulical integrated multifunctional construction machinery and highly constructed with the small, medium and large size

(8) Noise collecting system, sound proof system, compact and flexible equipment can further meet construction waste crushing work between cities. Suitable diesel noise pollution discharge system, effective dedusting system and release system can remote control the barriers in the portable crushing and screening plant while the pre-screening system can greatly increase crushing efficiency.

Parameters

DWT-VSI series Mobile VSI Crusher Plants | DWT-V 05 | DWT-V 06 | DWT-V 07 |

VSI Crusher type | VSI 5000 | VSI 6000 | VSI 7000 |

Max feed size(mm) | 65 | 70 | 70 |

Crushing capacity(t/h) | 80-150 | 120-150 | 180-350 |

Driving unit | |||

Engine | Cummins or CAT | Cummins or CAT | Cummins or CAT |

Power (kw) | 400 | 480 | 550 |

Feed hopper | |||

Hopper volume (m³) | 4 | 6 | 6 |

The feeding belt conveyor | |||

Belt width(mm) | 800 | 1000 | 1000 |

Discharging belt conveyor | |||

Belt width(mm) | 1000 | 1000 | 1200 |

Crawler unit | |||

Drive | hydraulic | hydraulic | hydraulic |

Dimensions and weight | |||

Working dimension | |||

L x W x H mm | 13767X3621X4425 | 13940X3820X4980 | 13940X3920X4980 |

Transport dimensions | |||

L x W x H mm | 14273x3543x4024 | 14320x3751x4130 | 14320x3851x4330 |

Weight (t) Approximately | 38 | 43 | 47 |

Note:

1. The processing capacity is the data when the density of the broken material is 1.6x103 kg/m3. The production capacity is related to the physical properties of the crushed material, the feeding mode, the feeding granularity and its composition;

2. Our products are constantly updated and improved, Devo reserves the right to change parameters and design without first notifying the user;

3. The above product configuration is not necessarily the factory standard configuration. Please consult us in detail when purchasing.

Contact Us

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU