HP Multi-cylinder Hydraulic Cone Crusher Introduction

HP Series Multi-cylinder Hydraulic Cone Crusher adopts high strength casting-steel frame, alloy forging main shaft and high precision straight bevel gear driving structure, combined with multi-chambers selection and automation control system, which fulfills the performance and advantages. It can be widely used in secondary and fine crushing work for all kinds of hard materials and rocks to meet customers' various needs for crushing. We have models: HP100, HP200, HP300, HP400, HP500,

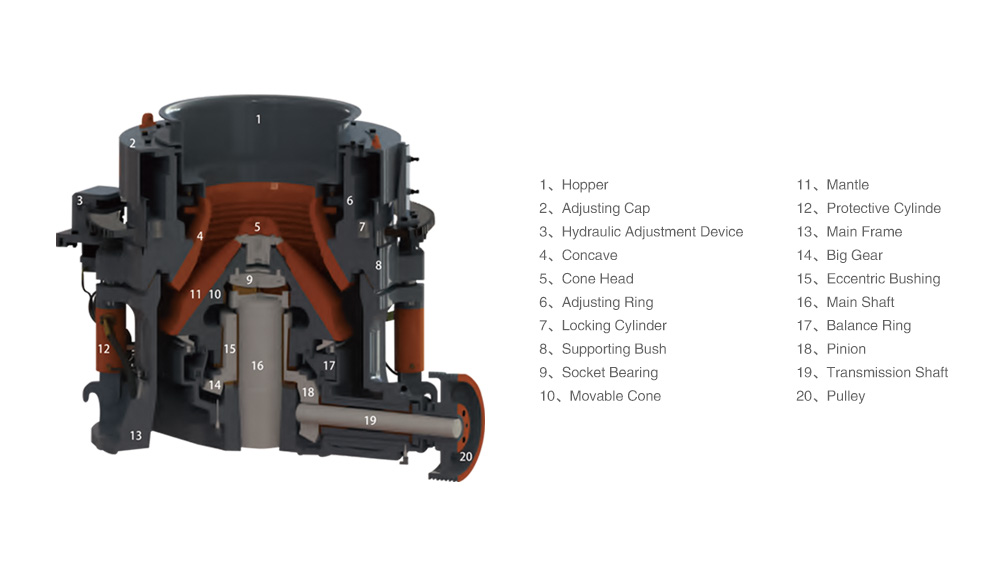

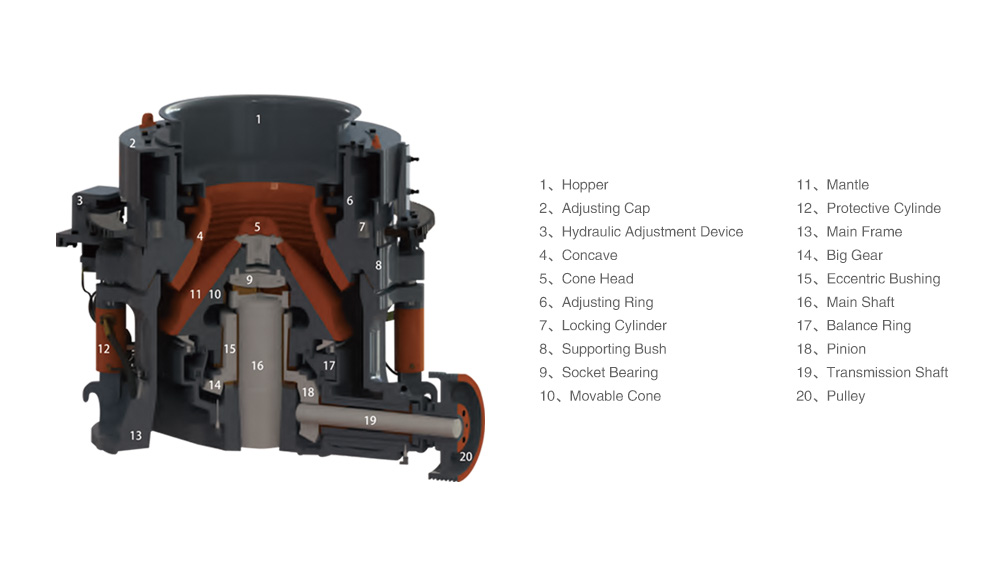

HP Multi-cylinder Hydraulic Cone Crusher Stucture

Multi-cylinder Hydraulic Cone Crusher Working Principle

When the crusher working, the motor drives the eccentric rotating through the drive shaft and a pair of bevel gear, cone axis does rotary pendulum movement under the force of eccentric sleeve , which makes the mantle surface sometimes near the concave, sometimes far from the concave, so that the ore in the crushing cavity is continually squeezed and being broken. The material enter into the crusher from the upper feed opening, by crushing can be discharged from the bottom discharge opening.

1. Long service life. The frame and main shaft are made of high-strength alloy steel for precision casting and precision forging;

2. Structural optimization design, Large capacity, Low operating cost ;

3. Wide product granularity requirements Range. It adopts various crushing cavities.

4. Fixed shaft design, the spindle does not move during operation, greatly increasing its strength and obtain greater installed power.

5. High automation degree. Hydraulic cavity setting reduces the amount of work required to remove the blockage material in the crushing chamber.

6. Hydraulic motor drive adjustment sleeve (fixed cone lining), greatly simplifies the workload of liner replacement.

7. The bronze sleeve used in this machine can provide greater load capacity in a vibrating environment with large vibration and dust.

8. All parts can be disassembled and maintained from the top or side, which is convenient to replace wearing parts.

RU

RU