Applications

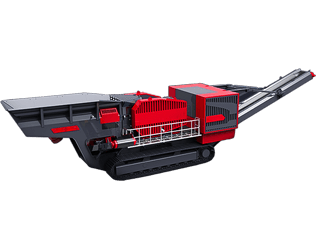

Product Introduction:

Tracked Mobile Impact Crusher Plant is furnished with XF series impact crusher. This type of crusher is especially suitable for quarry materials, construction rubble, paving stones and concrete. The size of 95% final products is smaller than 45mm. It can be optimally used as a primary crushing plant. The optional high performance magnetic separator can be effectively applied to the recycling industry. The plant is eminently suitable for the processing of natural stone and provides an excellent final grain size.

Scope of use:

It can be widely used in construction waste, mine, mining, sand and cement companies.

Product Features & Advantages:

(1) Two deck grizzly vibrating feeder makes optimal coarse screening, maximizing the total performance and reducing wear

(2) The internal space of materials directions open wider and wider, which prevents it from blocking. The decreased friction removes the abrasion of wear parts

(3) The material which has already the required grain size, is conveyed via a bypass past the impact crusher directly to the discharge chute. The efficiency of the complete plant is increased

(4) The diesel direct drive in combination with a power motor allows for a maximum performance at a small amount of space

(5) The hydraulic controlled mobile impact crusher guarantees constant product quality and high availability

(6) The processing plant is easy to operate with the remote control

(7) The active hydraulic permits a trouble free material flow via the movable inlet plate of the impact crusher

(8) For the optimization of performance and availability mobile processing plant is operated under intelligent control background

Parameters

DWT-PH Series Mobile Impactor Plants | DWT-PH10 | DWT-PH14 |

Feed opening size(mm*mm) | 810 x 1030 | 1025 x 1360 |

Max edge length in one direction(mm) | 800 | 1000 |

Crushing capacity(t/h) | up tp 250 | up to 420 |

Drive | diesel-direct | diesel-direct |

Driving unit | ||

Engine | CAT C9 | CAT C18 |

Power (kw) | 242 | 470 |

Feed hopper | ||

Hopper volume (m³) | 4.8 | 8.5 |

Grizzly feeder with pre-screening(two-deck) | ||

Model | GSF3712 | GSF5120 |

Drive | hydraulic | hydraulic |

The main belt conveyor | ||

Model | B1200 | B1400 |

Crawler unit | ||

Drive | hydraulic | hydraulic |

Permanent magnetic separator | ||

Magnetic separator | option | option |

The unearthed belt conveyor | ||

Model | B650 option | B650 option |

Dimensions and weights | ||

Working dimensions | ||

L x W x H mm | 14600x4500x4200 | 18000x6000x4800 |

Transport dimensions | ||

L x W x H mm | 13300x3350x3776 | 17000x3730x4000 |

Weight (t) Approximately | 43 | 70 |

1. The processing capacity is the data when the density of the broken material is 1.6x103 kg/m3. The production capacity is related to the physical properties of the crushed material, the feeding mode, the feeding granularity and its composition;

2. Our products are constantly updated and improved, Devo reserves the right to change parameters and design without first notifying the user;

3. The above product configuration is not necessarily the factory standard configuration. Please consult us in detail when purchasing.

Contact Us

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!

RU

RU